roll labels

& stickers

Because our labels are offered with a custom size option, you won't find a standard size listed on this page. You're free to choose any size or shape!

To order a bespoke shape, please choose the 'bespoke shape' option below. You will need to set up your artwork with a cutter guide, using a spot colour to represent the bespoke shape.

Tip: Avoid sharp edges in your bespoke shape design, as it may cause the label to tear when peeled from the backing.

Enter the number of different artwork versions you would like to print using the same product specification (size, quantity, substrate, lamination etc).

Additional artwork versions of this product will receive a discount.

Same Guide:

If each version of your label uses the exact same cutting guide to produce identical shapes.

Different Guide:

If you require a different cutting guide for each version of your label to produce different shapes.

White PP Plastic:

A water-resistant white polypropylene (PP) plastic film with a 59gsm face weight. Available in both permanent and removable adhesive options. You can use it in temperatures ranging from -20 to 80 degrees Celsius.

Super permanent adhesive is suitable for temperatures ranging from -40 to 70 degrees Celsius.

Clear PP Plastic:

A clear polypropylene (PP) plastic with sunlight resistant qualities and a 59gsm face weight. It's excellent for use on glass and is available in both permanent and removable adhesive options. Not available with lamination. You can use it in temperatures ranging from -20 to 80 degrees Celsius.

Paper:

A cost-effective, general purpose Label with an 81gsm face weight. It has a semi-gloss finish and is available in both permanent and removable adhesive options. You can use it in temperatures ranging from -20 to 80 degrees Celsius.

SUPER CLEAR PP PLASTIC:

A very transparent polypropylene (PP) material featuring a 43gsm face weight and a thin 23-micron backing liner. Designed exclusively with a high gloss finish, this substrate is only available with gloss coating or gloss lamination. It comes with a permanent adhesive, ensuring a secure and lasting bond for your applications. Suitable for temperatures ranging from -20 to 50 degrees Celsius, Super Clear PP Plastic combines clarity with a glossy aesthetic for versatile and impactful results. IF YOU ARE MACHINE APPLYING YOUR LABELS, PLEASE ENSURE COMPATIBILITY BEFORE USE.

Black PP Plastic:

A black, pigmented PP film with strong permanent adhesive. It has excellent UV resistance and ‘weatherability’. You can use it in temperatures ranging from -20 to 80 degrees Celsius.

Silver Metallic:

A glossy, silver metallic polypropylene Label substrate with a permanent adhesive. Print colour directly on top for a lustrous metallic effect or use with white ink for striking designs. You can use it in temperatures ranging from -20 to 80 degrees Celsius.

White PP Opaque:

A white PP substrate with an opaque metallic backing which prevents show-through when applied to pre-printed products. It has a permanent adhesive and is excellent for over labelling. You can use it in temperatures ranging from -20 to 80 degrees Celsius.

Information:

Coating and lamination are not available with Luxury substrates.

Rustique White:

An uncoated paper with a tactile handmade appearance and a 90gsm face weight. Its wet strength and fungicidal treatments make it good for craft beer or wine labelling. Suitable from -30 to 70 degrees Celsius.

Antique Creme Laid:

An uncoated cream FSC® certified paper with a subtle laid texture. It has good wet strength and fungicidal treatments, making it great for beverage labelling. It’s suitable for use in temperatures from -30 to 70 degrees Celsius.

Apple Touch:

A smooth, woodfree printing paper with an uncoated, matt finish. The face substrate is made with 5% apple waste from apple juice production and 95% FSC® certified pulp. It’s perfect for premium food and beverage products that need to capture a natural feel. It’s suitable in temperatures from -20 to 80 degrees Celsius.

White Embossed:

An uncoated, white embossed paper with a tactile laid texture. Its excellent wet strength and fungicidal treatments make it a perfect option for beverages like wine. Suitable for use in temperatures from -30 to 70 degrees Celsius.

Sirio Pearl Ice White:

A visually striking pearlescent paper, perfect for high-end cosmetic products or supplements. Suitable for use in environments ranging from -30 to 70 degrees Celsius.

Kraft Laid:

An earthy brown laid paper with a tactile, uncoated surface. The natural feel makes it perfect for food and beverage products with homemade appeal. Suitable from -30 to 70 degrees Celsius.

Requirements:

Removable adhesive is only available on White PP (excluding White PP opaque), Clear PP and Paper. Super permanent adhesive is only available on White PP and Rustique.

Semi-Permanent:

Semi-permanent adhesive is an excellent all-round choice for standard Labels. It's not suitable for use on rough surfaces, very small Labels, or Labels with special lamination, such as soft touch. We recommend semi-permanent adhesive on Labels intended for machine application.

Removable:

This gentle adhesive makes your Sticker or Label easy to remove from a surface and won’t leave residue.

Super-Permanent:

This is a high-strength adhesive suitable for permanent labelling. It's incredibly tough to remove and facilitates very long lasting Labels.

Below are the adhesion levels of your label

Glass

Unpainted Metal

Corrugated Card

Coated Card

Gloss Plastic PP/PE

Matt Plastic PP/PE

Textured Surfaces

Painted Surfaces

Choose from: CMYK, Black Only or Foil Only.

Foil Only Label

Order a Label with your selected foil colour and no other printed colours.

White Ink is only available for use on the following substrates:

- Black PP Plastic

- Clear PP Plastic

- Silver Metallic

Silver Ink is a mid-brilliance ink with a satin effect, similar to Pantone 877C. It can be used alone or with a CMYK topping to create a variety of metallic effects. We recommend printing solid rather than tinted.

If you want a glossy, metallised finish, try the Silver Metallic substrate instead.

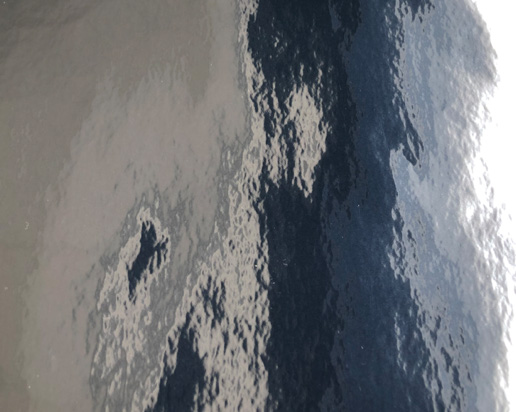

This image shows the difference between Silver Ink and Silver Metallic substrate.

If you want a glossy, metallised finish, try the Silver Metallic substrate instead.

This image shows the difference between Silver Ink and Silver Metallic substrate.

White Ink:

Available for use on black PP, clear PP and silver metallic substrates only, either for spot, tinted or a mixture of both.

Silver Ink:

This is a mid-brilliance silver ink, similar to Pantone 877C. It can be used alone or with a CMYK topping to create a variety of metallic effects. We recommend printing solid rather than tinted.

Use our free downloadable guides to find out how to set up artwork for special colours. Printed samples can be sent on request.

Requirements:

Coatings are not available with Luxury substrates.

Gloss UV coating:

For a glossy and scratch-resistant finish, we recommend a gloss coating on all high ink coverage Labels. Most writing instruments will not be able to write on this.

Satin UV coating:

Gives Labels a satin finish with a subtle surface shine. Like gloss, this coating is recommended for Labels with high ink coverage. Most writing instruments will not be able to write on this.

Matt UV coating:

Gives Labels a soft matt finish. This coating is not recommended for Labels with a high ink coverage where good scratch resistance is required. Most writing instruments will be able to write on this. This coating can give clear Labels a milky effect.

Rough Touch UV coating:

Gives Labels a sandy/rough finish. This coating is recommended for Labels with high ink coverage. You cannot write on this finish. This coating will give clear Labels a milky effect.

Overprinting and write-ability:

None of our Labels are guaranteed for machine overprinting, although some finishes can be written on with permanent markers. If you decide not to coat your Labels, we recommend you print them on our paper substrate, which is less glossy than the PP option.

The table below shows the gloss level, scuff resistance and writability of each UV coating finish offered. Generally, paper substrates are easier to write on and for high ink coverages scuff less, regardless of coating finish.

| PP substrates | Paper substrates | |||||

|---|---|---|---|---|---|---|

| Coating type | Gloss level | Scuff resistance | Writability | Gloss level | Scuff resistance | Writability |

| Gloss | High | High | Low | High | High | Low |

| Satin | Medium | Medium | Low | Medium | High | Medium |

| Matt | Low | Low | Medium | Low | Medium | High |

| Rough Touch | Medium | High | Low | Medium | High | Medium |

Requirements:

Laminations are not available with Luxury substrates or any substrate with Removable Adhesive.

Soft Touch, Anti Scuff and Linen Laminations are not available on Clear PP Plastic.

Foiling is not available with:

Coatings & Lamination:

- Gloss Coating

Substrates:

- Kraft Laid

Spot UV is not available with:

Coatings & Lamination:

- Gloss Lamination

- Satin Coating

- Gloss Coating

- Rough Touch Coating

Substrates:

- Apple Touch

- Sirio Pearl Ice White

- White Embossed

- Kraft Laid

You haven't selected a die to reuse.

Please choose a die from the dropdown, or Select "No" in the "Reusing a Die" section to continue.

Laser Cut

Laser cutting is suitable for most applications. It offers the fastest possible turnaround, flexibility in cutting shape/design, and typically costs less.

Die Cut

Die cutting gives a cleaner, more accurate cut than laser. Additionally, when high ink coverage bleeds over the cut edges you won't see the substrate colour showing through. This is suitable for dark coloured Labels being applied to dark-coloured products.

Die cutting is more suitable for machine applied Labels, although laser cutting can work just as well, depending on the exact application and circumstances.

Information:

- Laser cutting will be automatically selected when 'machine applied' is chosen, except when 'bespoke shape' is chosen.

- Laser cutting is not available with White PP Opaque Labels.

- Laser cutting is not available with White PP super permanent when a specified direction is chosen.

- Die cutting will be chosen automatically when the cost becomes less, although you can manually select die cutting. You can also manually select laser cutting.

- Die cutting adds 1 working day to the production time.

- Die cutting is available with Express or Express Plus for certain Label specifications, depending on availability.

- For die cutting, the minimum radius corners on all substrates is 0.5mm.

Laid substrates have a repeating lined pattern on their surface. You’ll need to choose whether you want the lines on your Label to run horizontally or vertically.

Applied By Hand

We will automatically select the most cost effective options for Labels that are being applied by hand.

Applied By Machine

If your Labels are being applied by a machine, you will need to check the specific requirements of your labelling machine before choosing any of the options listed. Please observe the orientation messages when you add to the basket.

If you are planning to apply your labels on a machine then you may want to specify the direction the label leads with on the roll.

If you are applying your Labels by hand, we have automatically selected the most cost-effective orientation for you.

If you apply your Labels using a machine, you can choose whether they are wound facing outward or inward.

You have the option to change the core diameter size of your Label roll if you plan to apply them with a machine. Choose from 3 sizes: 76mm, 38mm and 25mm.

The measurements shown are inner diameters (ID). The default ID is 76mm. We recommend the 76mm size for Label application by hand.

Requirements:

Roll widths below 35mm can have maximum roll diameters up to 165mm.

Roll widths below 50mm can have maximum roll diameters up to 200mm.

You have the option to reduce or increase your roll diameter for manual Label application. If you’re distributing rolls of Labels to multiple users, you may want to reduce this.

The actual approximate outer diameter of each roll is displayed in your order summary, along with the number of Labels you will receive on that roll.

This allows you to select a larger gap between your labels, this can be useful for some machine applicators. The default is 3mm for polypropylene and 4mm for papers.

You can change how sharp the corners of your square or rectangular Labels are. Choose from 0mm to 10mm, depending on your substrate, finished size and cutting method.

Machine application: we recommend die cutting and a minimum corner radius of 0.5mm.

Information:

Laser cutting - The minimum radius is 0mm on PP substrates and 1mm on paper substrates.

Die cutting - The minimum radius on all substrates is 0.5mm.

This option allows you to specify the number of labels across each roll.

This option is recommended for hand-application only, as machine application requires Labels to be laid out in single file down the length of a roll.

We will automatically calculate all the possible roll configurations for your given Label size, and you can choose whichever suits you.